OPERATIONS

PEOPLE

Globally, AGY has over 600 employees involved in production, sales and marketing, distribution and development of our range of glass fiber products.

Over the years, AGY has maintained an excellent record of employee retention. Our employees have an average of 17 years of service with over 60% having greater than 10 years and over 40% having greater than 20 years. We offer an attractive benefits package which includes medical, dental and visions options, as well as an on-site Primary Care Physician at our Palmetto Proactive Wellness Clinic and a 24-hour on-site Fitness Center. AGY is an Equal Opportunity Employer.

Keeping our employees safe is the number one priority at AGY. We have historically set very aggressive internal safety performance goals, and while we have not always achieved these goals we’ve set for ourselves, our safety performance has been far superior than the industry average. Over the last nine years, the OSHA Recordable Incident Rate (ORIR) and Lost Time Rate (LTR) have averaged 55% lower than industry average, and the Days Away and Restricted Time Rate (DART) has averaged 39% lower than industry average.

AGY is a proud member of the Aiken Chamber of Commerce. We have participated in such community events as the Aiken Relay Golf Classic – benefiting the Relay for Life and the American Cancer Society, the Walk for Autism, the Light the Night Walk – benefiting the Leukemia and Lymphoma Society, and we have given to such organizations as the Red Cross, the United Way and the Muscular Dystrophy Association.

The community and its residents are an important part of what makes AGY who we are. Therefore, we strive to help maintain a healthy environment and to give back to worthwhile organizations.

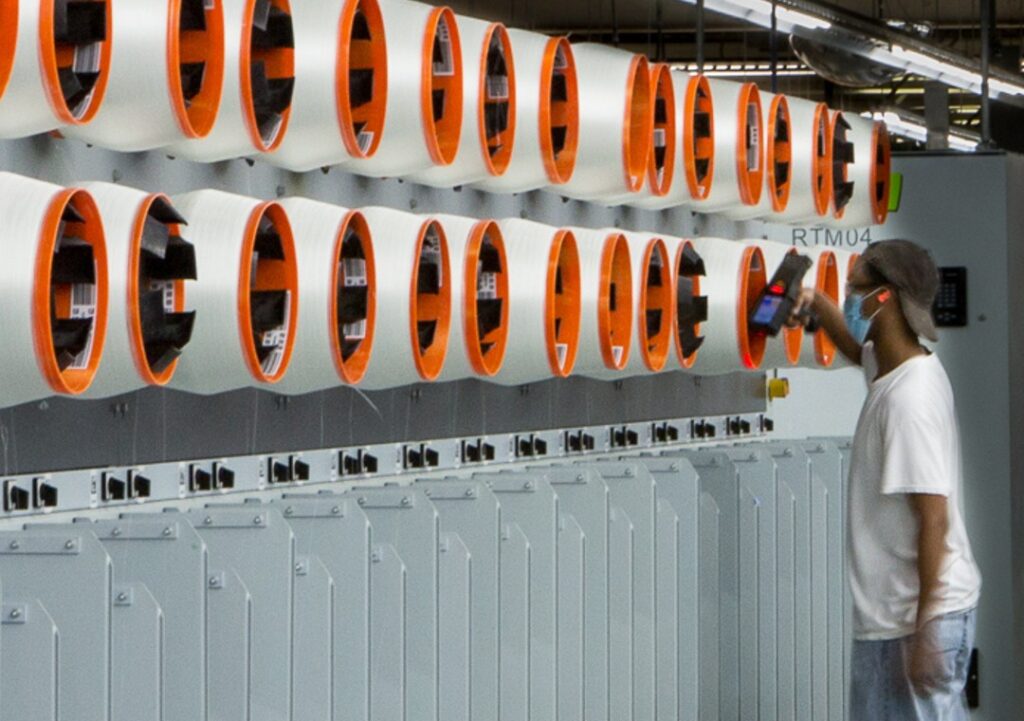

AGY’s Operations department makes up over 80% of our entire workforce. It is comprised of the following areas:

Advanced Materials, Technical Fibers, Quality, Supply Chain, Capital Projects, Education and Development, Maintenance, Batch and Furnace, HESS, Strategic Sourcing and Industrial Relations

The Advanced Materials and Technical Fibers plants include forming, fabrication, and special fab operations which in turn incorporate engineering, chem prep and alloy engineering.

If you would like to learn more about our career opportunities in any of these areas, please visit our Careers link.

PROCESS

The AGY manufacturing operation is divided into two primary business units:

Technical Fibers

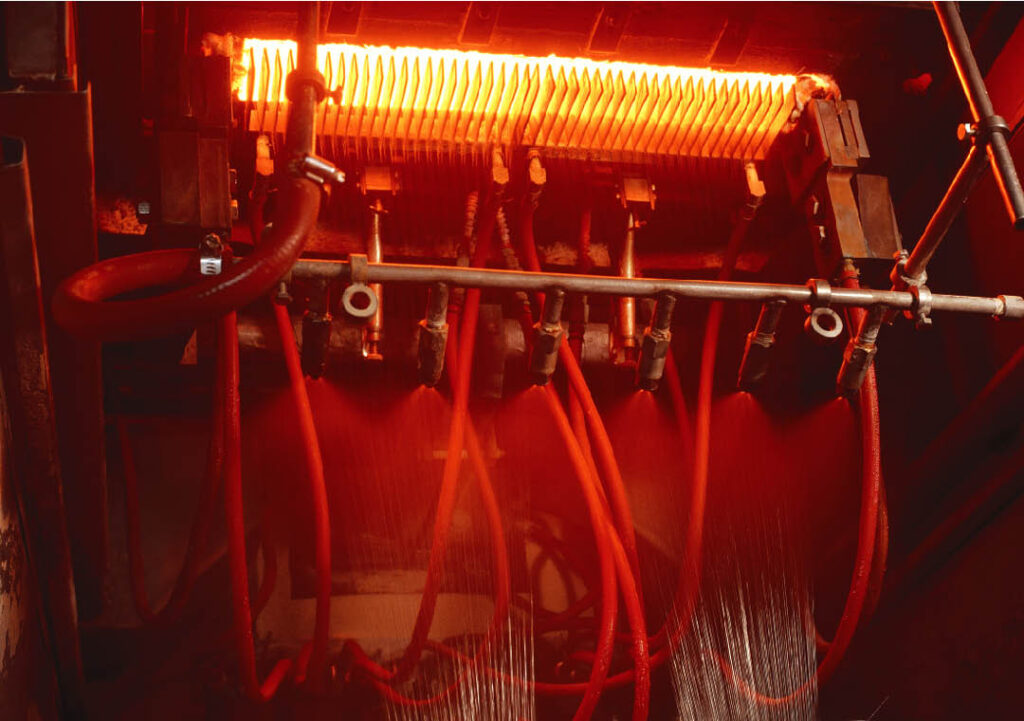

The Technical Fibers business unit supports our E-Glass portfolio of products. The customers serviced by this portion of the business are in a wide variety of markets and applications such as aerospace, electronics, automotive and sporting goods. In Technical Fibers, glass is produced using a Direct Melt process that combines ingredients to create an E-Glass formulation. Raw materials, such as sand, clay, and limestone are mixed together and fed into a refractory furnace which has oxygen-gas burners and electrodes to provide the energy required to heat the batch mixture to nearly 3000°F, creating molten glass. Glass flow is then cooled and distributed to several forming positions (bushings) to create the fiber glass input to our other processes. Typical fiber diameter used in our technical fiber products are 6 to 9 microns, roughly a fifth to a tenth of the diameter of a human hair.

Advanced Materials

The Advanced Materials business unit supports the products made from all of the other glass types offered by AGY, such as S-2 Glass yarns, S-2 Glass rovings, S-2 Glass chop, L-Glass yarns, L-2 Glass yarns, ZenTron and VeTron rovings, S-3 HDI Glass yarns and some specialty E glass yarns. These products support a wide variety of markets such as defense, aerospace, electronics, and architectural roofing, as well as some specialty medical and sporting goods applications. In Advanced Materials, glass is fiberized using one of two different melting technologies with either batch ingredients or pre-formed glass marbles as the input. Depending on the product, the fiberized glass filaments will range in diameter from 4 to 24 microns, a fraction of the size of a human hair. Filaments are then coated with a chemical binding agent or a starch oil product, called a sizing system, to create singular strand. Fiberizing process speeds can reach up to 10,000 linear feet per minute.

Once formed, products from either business unit move through the facility where the strand packages are further processed by one of the following processes:

Twisting – Mechanically twisting the input onto one of several different bobbin configurations which creates a yarn.

Chopping – Mechanically chopping the fibers to a specified length, from 5/32” to 2”(4mm to 50mm).

Roving – Assembly of several strands together into a package, this is called the roving process.

PERFORMANCE

AGY uses a range of different operating metrics throughout the glass making process to gauge performance for any period of time. We continuously monitor a multitude of variables to ensure we are making the best glass fiber products possible for our customers. Some of our metrics include:

- Efficiencies in our forming and fabrication areas

- Number of breaks in our glass product per hour

- The restart times for forming positions which have broken out or are in need of repair

- Number of bushings running in the facility

- The length of time a bushing operates

- Volume of a product we are producing

- Number of full packages created vs. partial packages

- The percent of returns vs. sales

These are just a few of the metrics that AGY measures on a daily basis to ensure a smooth operation from start to finish. Our goal is to always strive to improve our process and our products to our customers. Therefore, the goals set for these measures and others continue to be more and more stringent each year. And AGY has delivered! We are making better glass, more efficiently, than ever before.

AGY continuously strives to make the highest quality product for our customers. In the past five years, AGY has seen a 60% reduction in the percent of quality returns. This is due, in part, to the significant improvements we have made, and continue to make, to meet our customers’ stringent quality requirements. These requirements can change with the demand of the marketplace, so it is important that AGY continually works toward improving upon the quality of our products and processes in order to meet a higher quality standard.

Customer audits are performed periodically to ensure that AGY maintains the appropriate Process Control Documents (PCD) and the proper materials, equipment, and procedures in order to meet the specifications of the product or group of products offered. Additionally, as technology continues to advance resulting in smaller and faster platforms of communication and data transfer, our customers are requesting smaller yarns that meet more rigorous fitness-for-use requirements.

Consistency is key. The more consistent AGY is in following our procedures, minimizing process upsets, and ensuring our products meet internal specifications, the higher quality our products will be when delivered to the customer. Having consistent procedures and quality processes in place internally help AGY to ensure we are routinely meeting the external customers’ needs.

Environmental performance at AGY is outstanding!! We operate under a Title V Air Permit with stringent requirements, and we adhere to 100 annual reporting requirements. AGY also works diligently to keep our emissions low for the betterment of our environment. AGY successfully operates its own certified wastewater treatment facility that is managed in accordance with all state and federal requirements. We work hard to keep the environment clean.

As part of our continuous effort to provide the highest quality products, AGY is ISO 9001:2015 certified, and has been since 1993. For a copy of our ISO certification, please click here.